Small enterprises face tough challenges meeting global food standards

As Cambodia expands agricultural exports and places greater emphasis on small and medium-sized enterprises (SMEs) it is increasingly having to meet strict global food safety standards. The problem is that there are few food safety auditors or testing labs in the Kingdom and very little information in Khmer.

Meeting safety standards is vital for global exporters. More than 200 diseases, from diarrhoea to cancer, are caused by contaminated food. One in ten people worldwide get sick from food and at least 220,000 die every year. If you include the disease and malnutrition caused by contaminated food, the total is closer to a quarter of a million deaths.

Guillaume Maltaverne, Trade Information and Advocacy Advisor at ARISE+ Cambodia, said the topic is wide and complex.

“Food safety is about consumer protection, to make sure when you eat it is safe. Otherwise you can have experiences such as food poisoning and more serious health risks. The best solution is a preventative approach to prevent food being contaminated by hazards and, to do so, the preventative approach would be based on standards and certification which are internationally recognised,” he said.

ARISE+ is an EU-German collaboration which has a specialised team working with SMEs on exports. It currently helps 15 companies along with business associations in Cambodia.

Maltaverne said that the issue is so complex that one country’s problems are likely to have knock-on effects. He gave the example of Cambodian longan exported to Thailand for re-export to China. The fruit was banned by China after it found pests on Thai longan, with the ban also affecting Cambodian exports. Now that China and Cambodia have a free trade agreement the Kingdom is looking to export more food products directly and has been working hard at creating phytosanitary facilities to treat fruit.

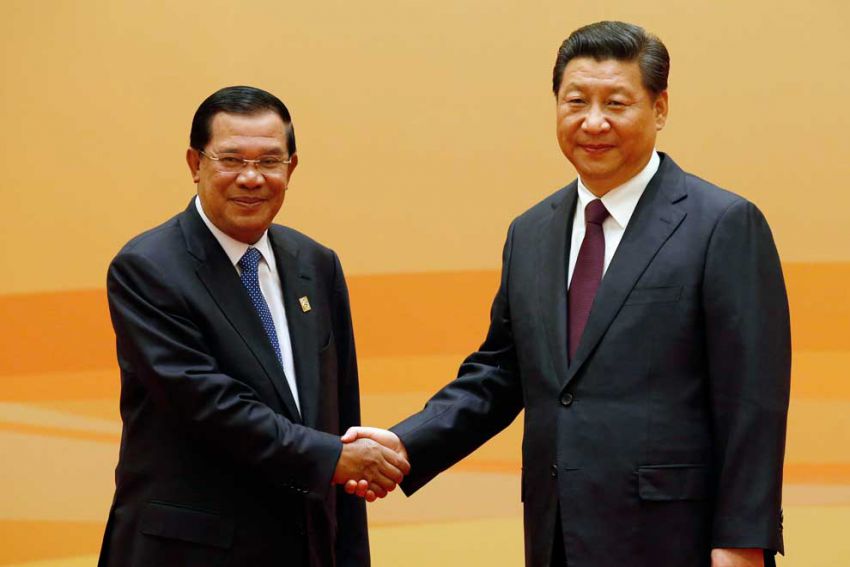

Yuong Rathana, is one of Cambodia’s few qualified food safety auditors, working at Control Union in Phnom Penh.

She said commitment and involvement from top management is vital to ensure food safety. She advised companies to establish a food safety team, which should amass expertise and adopt a multidisciplinary approach. Staff must receive ongoing training and not just rely on management’s knowledge of the issues. Finally she said companies should look at which of the myriad food safety guidelines are suitable for the products they are exporting.

Being equipped to meet stringent standards requires a big commitment from small companies. Rathana said they need to renovate the buildings they use, even if they work out of their own homes. The estimated cost of bringing a 62 square metre building up to scratch is $13,000.

Meas Holy knows all about the cost and confusion of meeting global food standards. He is the sales manager of Kirirom Food Production. The company wanted to tackle the huge waste and lost sales caused by the vast numbers of mangos thrown away by farmers during the harvesting season. From 2014 it started selling processed fruit and now produces up to 100 tonnes a day of mango products, employing as many as 900 workers.

“From the start we turned our key project to overseas companies. When we gave companies the details of our project, they promised to buy it from us in whatever the amount. Unfortunately when we produced the product, they said it does not meet their requirements and rejected it at that time.”

The company received help in getting certification from the Ministry of Industry, Science, Technology and Innovation and now has the documents to satisfy the pickiest buyers in Asia, Europe and North America. Its products are also certified as Halal and Kosher. It uses the downtime between mango seasons each year to renovate its buildings to meet ever-stricter global food safety standards.

Kirirom then went back to its marketing team to sell its certified products overseas with an updated website and a listing on global e-commerce site Alibaba.com, a strategy which bore fruit during the Coronavirus pandemic. Kirirom’s domestic sales dropped to nearly zero, meaning nearly 100 percent of its business was through exports.

Now one of the company’s biggest challenges is spreading the word on food safety to its suppliers and distributors.

“We buy most of the raw material from local suppliers, like plastic, packaging and sugar,” Holy said. “Those products are good. We can use them but the problem is when we request any documents such as the certificate of analysis from them, they say no, they only have the product.”

Persuading suppliers go get the certification is not easy since there are very few laboratories in Cambodia able to carry out the relevant tests and licenced to issue documentation acceptable to overseas authorities. The challenge is so great that EuroCham, the organisers of the food safety seminar, had to bring in a speaker from Vietnam.

Oanh Dinh was trained in Israel and has seven years’ experience working in Europe, the US and at home in Vietnam. She is now Key Account Manager at Bureau Veritas AQ Vietnam, based near Ho Chi Minh city. The company can carry out tests and provide documentation for export to countries and territories including the EU, US, China, Japan and South Korea.

“The laboratory can provide analysis, resulting in data on raw materials, semi-finished and finished products from farm to fork,” Dinh said. “We will help you to detect microbiological, chemical and physical hazards to prove your products are properly manufactured to the health and safety of consumers.”

She said identifying problems with food will help companies survive and grow their business in the long term as well as preserving a good brand image. Khmer Times