Garment industry ‘needs to modernise’ to survive in competition

With more than 500 factories across Cambodia the garment industry is the mainstay of the economy with clothing and footwear accounting for around 80 percent of the Kingdom’s annual exports but there have been growing calls for it to modernise or lose out to its global rivals.

Before the Coronavirus pandemic hit around 800,000 people were directly employed making garments and shoes. Around 150,000 staff lost their jobs or had to work fewer hours as a result of the pandemic.

The garment sector is the least digitally transformed industry in Cambodia, according to LT Labs. The tech solutions firm is a unit of Hong Kong’s Luenthai group, which makes garments in 20 affiliate factories across Southeast-Asia. LT Labs started offering its products to other manufacturers in 2019, promising to increase efficiency, reduce waste and gather the data needed to further improve the supply chain.

LT Labs uses touch-screen technology to inspect fabric for defects and upload pictures to the Cloud. Its data determines the average speed of workers, allowing managers to tell which operators are most effective on which machine. In-line and end-line production is monitored in real time and displayed on large screens so the entire factory can see where delays are happening. LT Labs also provides data to brand owners such as Adidas, allowing them to gauge the efficiency of the factories they use.

The company provides training in the Khmer language to staff and managers.

LT Labs is currently targeting factories with at least 2,000 employees but says in a few years it will roll out an LT Light plan for smaller factories employing around 500 workers.

“Many people think that automation necessarily means fewer jobs, which can be true in some areas but actually might help the entire sector in this country,” said Massimiliano Tropeano, an integrated expert from German development agency GIZ at the European Chamber of Commerce, where he works as Senior Garment Sector Advisor. “There are two areas where new technologies are working. One is the Internet of Things which is all the sensors related to the production and the machines. The other one is robotics, robotic arms or automated machines that are able to do one or another operation. This not only involves capital that the factories don’t have but also huge research. A push in regard to new technologies will mean a better skilled labour force,” he said.

Tropeano said large factories that deal with major international fashion houses should find it easy to adopt new technology but smaller manufacturers need government support for equipment and worker training.

Ath Thorn, President of the Coalition of Cambodian Garment Workers Democratic Union said improvements in infrastructure and lower electricity and water prices would help garment factories become more competitive, he also said training was needed in order to bring in technological improvements.

“Cambodia should strengthen workers’ skills in order to respond to the Fourth Industrial Revolution,” he said. “When factories adopt high tech solutions to improve productivity there will be some job losses in garment factories. There are pros and cons, workers need higher skills with joint training from the Ministry of Labour and vocational training. Cambodian workers need updating on high-tech machinery and new fashion styles.”

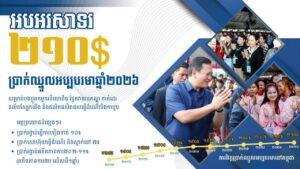

Cambodia’s minimum wage has risen by $2 every year from 2020 through 2022. Thorn says rising wages are will not hurt the garment industry’s ability to compete with overseas rivals.

“Employers and the government seem worried about competitiveness against global rivals,” he said. “In fact, workers need higher wages to improve their livelihoods and increase productivity in the factory. After the minimum wage has risen it has not impacted the garment sector because when Cambodian workers get higher incomes it helps employers increase productivity and be more competitive in the global market.”

Thorn said the government could help workers in other ways, such as by helping make everyday goods more affordable for workers. Khmer Times